We have production facilities to accommodate manufacturing using plastic resins such as Polypropylene (PP), Low/high Density Polyethylene(LDPE/HDPE) and linear Low Density Polyethylene(LLDPE)

We are always on the look for ways to improve our manufacturing process and production line to be ready to accommodate and more challenging demands of our client. And most importantly, our ongoing objective is to work closely with our clients in order to achieve the best possible result in term of quality, delivery and cost efficiency.

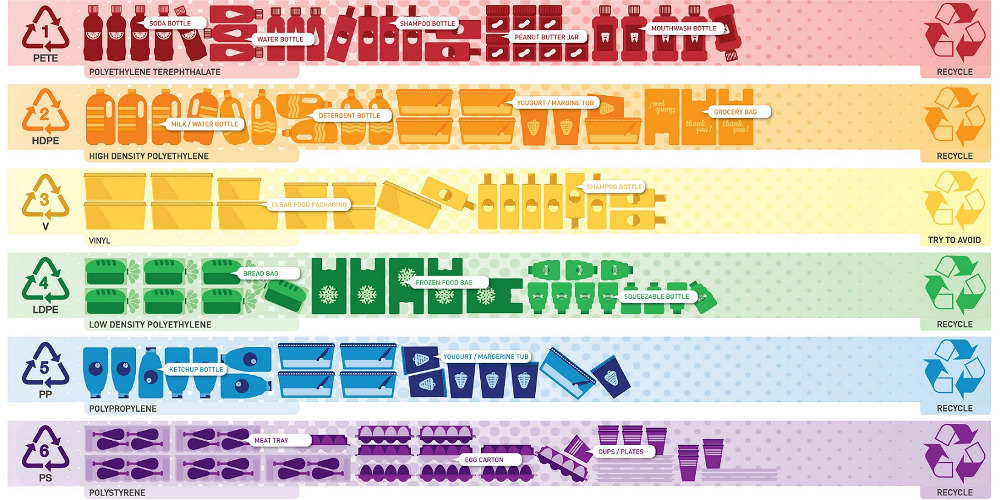

PET (Polyethylene Terephthalate)

The initial use of PET is as a man-made fiber, film and tape. In 1976, PET was widely used in beverage products , and the most common product was plastic bottles

HDPE(High Density Polyethylene)

In a modern life, HPDE can see everywhere in the use of many kind plastic. Moreover, majority of transparent and none transparent plastic was made of HDPE. Example, detergents, bath & shower, cooking oil and agricultural chemical.

PVC(Polyvinylchloride)

PVC has it own unique component and widely use nowadays. It can be used to manufacturer drinking straw, rain cloth, bags, plastic film, plastic box. Dioxin is one of the most deadliest of man-made poisons and it’s a cumulative toxin, meaning it stay in the body for a long time, concentrating in food chains at the highest level in carnivores-Which include us.

LDPE (Low Density Polyethylene)

LDPE’s lower density and branched molecules give it somewhat different properties than HDPE, although they do share some similar uses, such as packaging. LDPE is resistant to impact (doesn’t break easily), moisture (water proof), and chemicals (can stand up to many hazardous materials). LDPE is widely used for manufacturing various containers, dispensing bottles, wash bottles, tubing, plastic bags for computer components, and various molded laboratory equipment. Its most common use is in plastic bags. Other products made from it include: Trays and general purpose containers.

PP(Polypropylene)

The use of polypropylene in everyday applications occurs because of how versatile this plastic is. For example, it has a high melting point compared to similarly weighted plastics. As a result, this product works very well for use in food containers where temperatures can reach high levels - such as microwaves and in dishwashers.

PS(Polystyreme)

Poly(phenylethene), commonly known as polystyrene, is the third most important polymer, in terms of amount made from ethene. Its physical properties can be adjusted to suit a range of everyday uses. Techniques have been developed which increase its mechanical strength, its ability to absorb shock and its thermal insulating properties. The largest use for poly(phenylethene) is for packaging, particularly for foods such as poultry and eggs, for cold drinks and take-away meals.